Milk Processing

- Projects

- Milk Processing

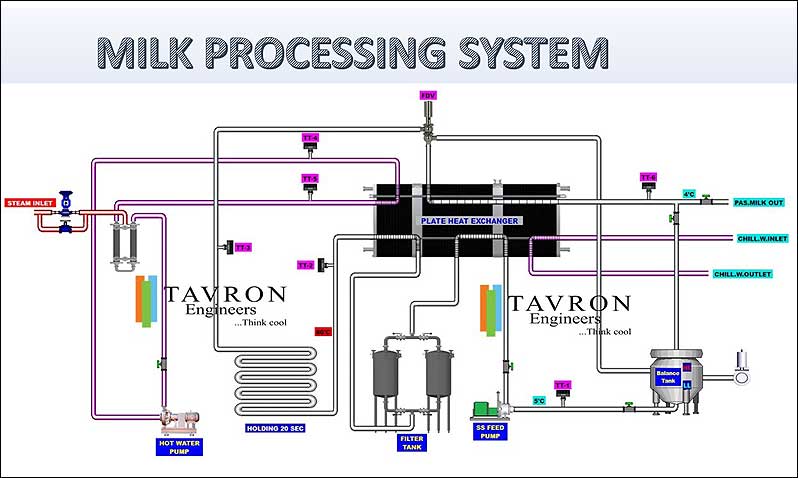

HTST MILK PASTEURIZER

-

HTST Pasteurizer for

Milk, Juice and other liquid product.

-

Cap From 50 LPH30,000

LPH.

-

Version Available with

Manual/Automatic.

-

Skid mounted / Floor

Mounted.

Tanks

-

Tanks with SS 304 / SS

316 Construction.

-

PUF Insulation for

better thermal stability.

-

Finished to the

International Standard.

-

Rotary Spray Ball to

cover the CIP all over the tank.

-

Fitted on the Legs with

Adjustable Ball feet.

-

Agitator with Reputed

make Geared Motor.

-

Air Vent with Hygienic

Standard.

-

Level Transmitter as

optional.

-

Temperature Transmitter

& Temperature Indicator.

-

Outlet with Hygienic

Valves.

-

Constructed with 2000 L

/ 3000 L / 5000 L / 10,000 L .

PLATE HEAT EXCHANGER SYSTEM

- Glue Free Gasket.

- Hygienic Plates.

- CIP Cleanable.

-

Plates are of SS 304/ SS

316.

-

Gasket are of NBR/EPDM.

STAINLESS STEEL CENTRIFUGAL PUMPS

-

Centrifugal type coupled

to Electric motor / Monobloc version.

-

Capacity 500 LPH to

1,00,000 LPH.

-

Head up to 60 MWC.

-

Applications transfer of

various liquids.

-

Material of construction

SS 304 / SS 31 6.

-

Suitable for operation

under vacuum.

-

Open impeller design

suitable to handle viscous products, pulps etc.

-

Monobloc version.

coupled to petrol or diesel engine are also available.

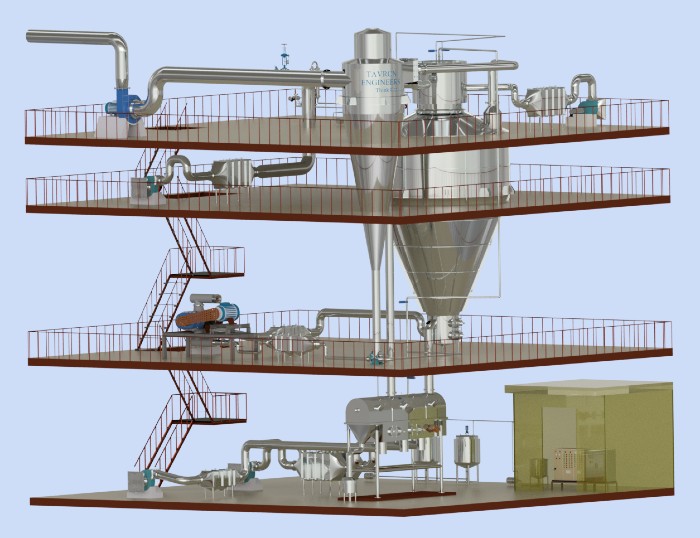

Spray Dryer

-

Capacity from 5 Kg / Hr

Water Evaporation to 1500 Kg / Hr Water Evaporation.

-

Available with Rotary

Atomizer, Nozzle and two fluid system.

-

Material of construction

SS 304 / SS 316.

-

Second stage drying with

Vibro fluid Bed Dryer.

-

Three Stage Drying with

Stationery Fluid Bed and vibro fluid bed.

-

Available with the hot

air producing system of steam, Direct or Indirect oil fired,

Thermic fluid etc.

-

Closed Loop Dryer is

available on request for special application.

CIP System

-

Suitable to Dairy /

Beverage Industries.

-

Automatic and Semi

automatic.

-

Single circuit to multi

circuit.

-

SS 316 construction.

-

Reputed make valves.

-

PLC with SCADA system.

- SKID Mounted.

- User friendly.

- Highly Efficient.

IBT System

-

Designed with R22 , R404

A , other Freon based Gas on request.

-

To handle the milk from

1000 LPD to 20,000 LPD.

-

Mild steel or Stainless

Steel construction.

-

Scroll or Reciprocating

Compressor.

-

PLC based controls on

optional.

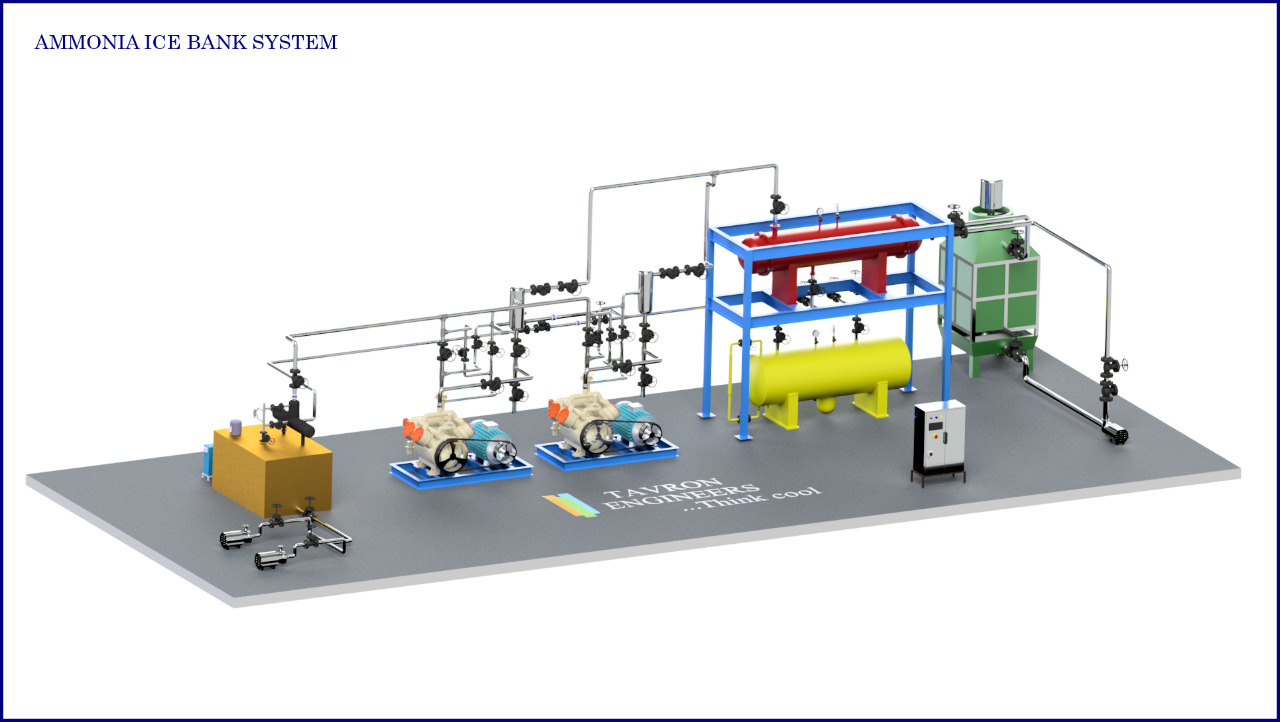

Ammonia IBT System

-

Designed with

Ammonia-NH3.

-

To handle the milk from

10,000 LPD to 5,00,000 LPD beyond this will be designed on

request.

-

Atmospheric / Shell &

Tube / Plate Type / Evaporative Condenser.

-

IBT System to have

enough ice storage to handle designed capacity of milk.

-

Return water Chiller as

optional.

-

Falling Film Chiller as

optional.

-

Glycol System as

optional.

-

PLC based controls on

optional.