Advantages of Evaporation

- Removal of water from solution.

- Provides microbial stability.

- Reduce chemical reaction.

- Reduce transportation and storage cost.

- Concentration of Solution

- Foaming

- Scale Formation

- Temperature Sensitivity

- Material of Construction

Parameters considered while designing Evaporator,

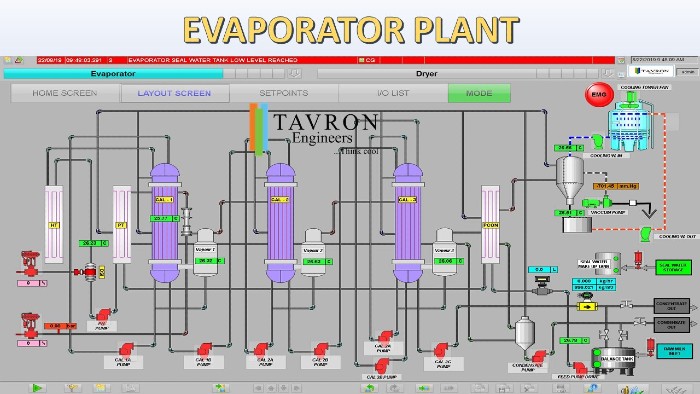

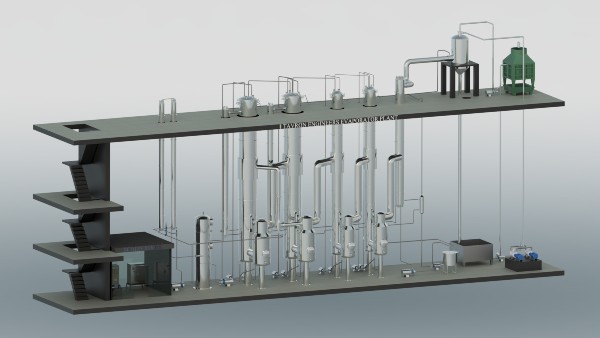

Tavron Engineers design, Manufacture, Erect and Commission different types of evaporators based on the customer requirements.

Types of Tavron Evaporator Design

- Falling film Evaporator.

- Raising Film Evaporator.

- Force Circulation Evaporator.

- Combination of falling film and force circulation Evaporator

SINGLE EFFECT EVAPORATORS

- When a single evaporator is used, the vapor from the boiling liquid is condensed and discarded. This is called single effect evaporation. It is simple but utilizes steam ineffectively.

- Construction with SS304/SS316

MULTIPLE EFFECT EVAPORATORS

- Increasing the evaporation per kg of steam by using a series of evaporators between the steam supply and condenser is called multiple effect evaporation.

- Optimum use of steam

- Construction with SS304/SS316

COMPONENTS OF EVAPORATOR

CALENDRIA

- Tubes are of A 319 or ASTMA 249.

- Shell will be of SS 304 / SS 316 / Carbon steel.

- Finished to Hygienic standard.

- Designed to achieve uniform wetting

- The Calendria has been designed with Single pass and multi pass.

- The calendria for the food industry is designed with the multi pass to avoid contamination.

EVAPORATOR ACCESSORIES

- Pre heaters are of straight tubes.

- Pre heaters are designed to use the vapour of calendria for heating the inlet product.

- Excellent designed Vapour separator to avoid carry over.

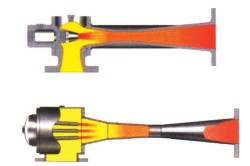

THERMAL VAPOUR RE-COMPRESSOR

- TVR with Single Nozzle.

- TVR with Multi Nozzle.

- TVR Material of Construction SS 304 / SS 316 / Carbon Steel.

- Suction and Discharge of various connection to suit the operational condition.