CIP System

- Food and Dairy Production is unimaginable without “Cleaning in

Place” systems.

- CIP means the automatic cleaning of production plants – without

them having to be disassembled or substantial changes being made compared to their production state.

- Hygiene and production safety are the basis for success in Food

and Dairy Industries.

- TAVRON CIP Systems fulfils these requirements.

- TAVRON CIP Systems can be equipped with one to four (or more)

tanks – pre-rinse water tank, caustic tank, acid tank and/or Hot water tank

- To this is added the number of desired CIP loops, i. e. the

number of cleaning processes running at the same time.

- The modular design allows our CIP Systems to be easily

customized and expanded.

- The CIP modules are completely pre-assembled and due to their

compact dimensions are easily transported. The required tanks are assembled on site next to the CIP

modules and connected with the prepared piping.

- Skid mounted Module unit.

- With Pneumatic Butterfly Valve and Pneumatic Seat Valve.

- Tanks with SS 316 inner and SS 304 outer.

- Single Circuit and Multiple Circuit.

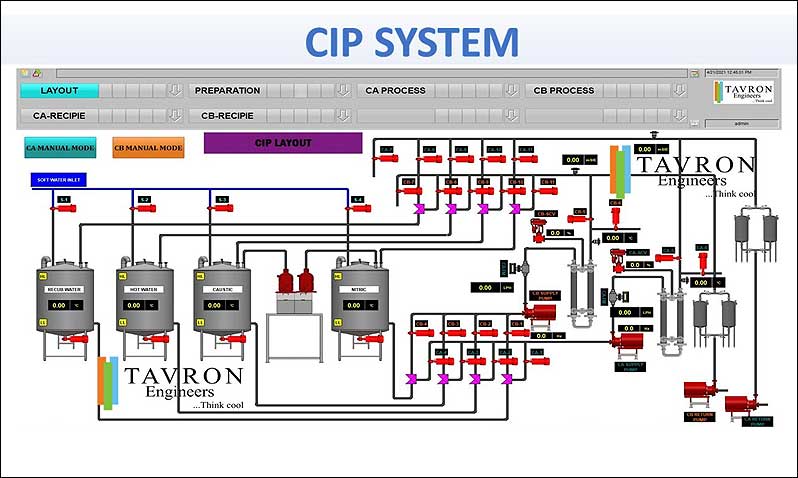

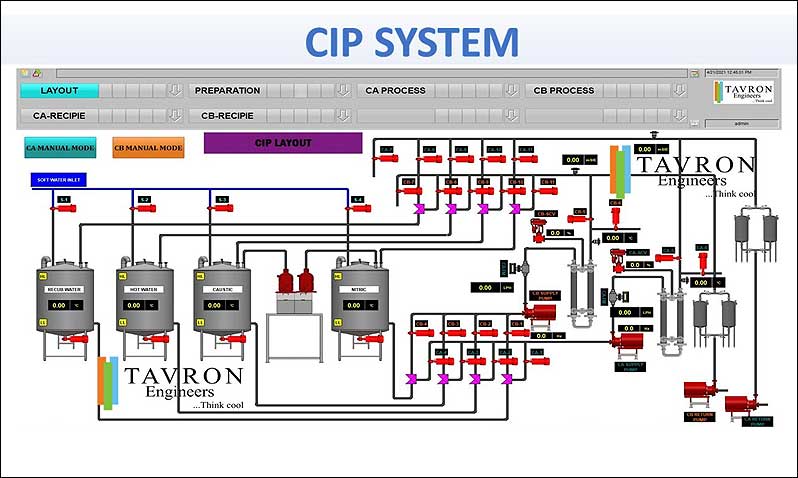

- PLC with HMI for ease of operation ( optional with SCADA )

- Flow meter, Conductivity meter for controlling the parameters.

- Standard flow sequence or Customised flow sequence.

- The TAVRON CIP System is controlled by a operator panel. The PLC cabinet is attached to CIP Skid.

- The Siemens S7 PLC Controller or Delta AS Series PLC Controllers are used as per the customer requirement.

Technical Data

Typical output for One CIP Supply Centrifugal Pump:

- 20,000 l/h at 4 bar pressure, 5.5 KW or

- 30,000 l/h at 5 bar pressure, 7.5 KW or

- 40,000 l/h at 5 bar pressure, 11 KW

- (A flow rate of at least 1.5 m/s is recommended for pipe

cleaning)

- TYPICAL TEMPERATURES CAUSTIC (NaOH): 70–90 °C

- TYPICAL TEMPERATURES ACID (HNO3): 0–70 °C

- DISINFECTION: Cold or Warm

Advantages

- Optimized Cleaning Times.

- Minimized Down Times.

- Highly Efficient Cleaning.

- Lower Personnel Costs Compared To Manual Cleaning.

- Reduction In Material Costs Due To Controlled Use Of Chemicals

Etc.

- Compliance With And Monitoring Of Required Cleaning Parameters

(Flow- Rate, Concentration And Temperature).

- Operator User-friendly HMI Design for Ease of Operation.